They have a quick opening and closing quarter turn function that controls the flow of liquids or gases. Read More…

Butterfly Valves & Controls, Inc. has been a premier supplier of quality butterfly control valves and other related industrial components for 25 years. We carry only the best parts sourced from world-class butterfly valve manufacturers. Extended service life and safe operation are at the core of every valve manufactured/assembled. Our catalog includes a large selection of valves, actuators, controls, positioners, and more.

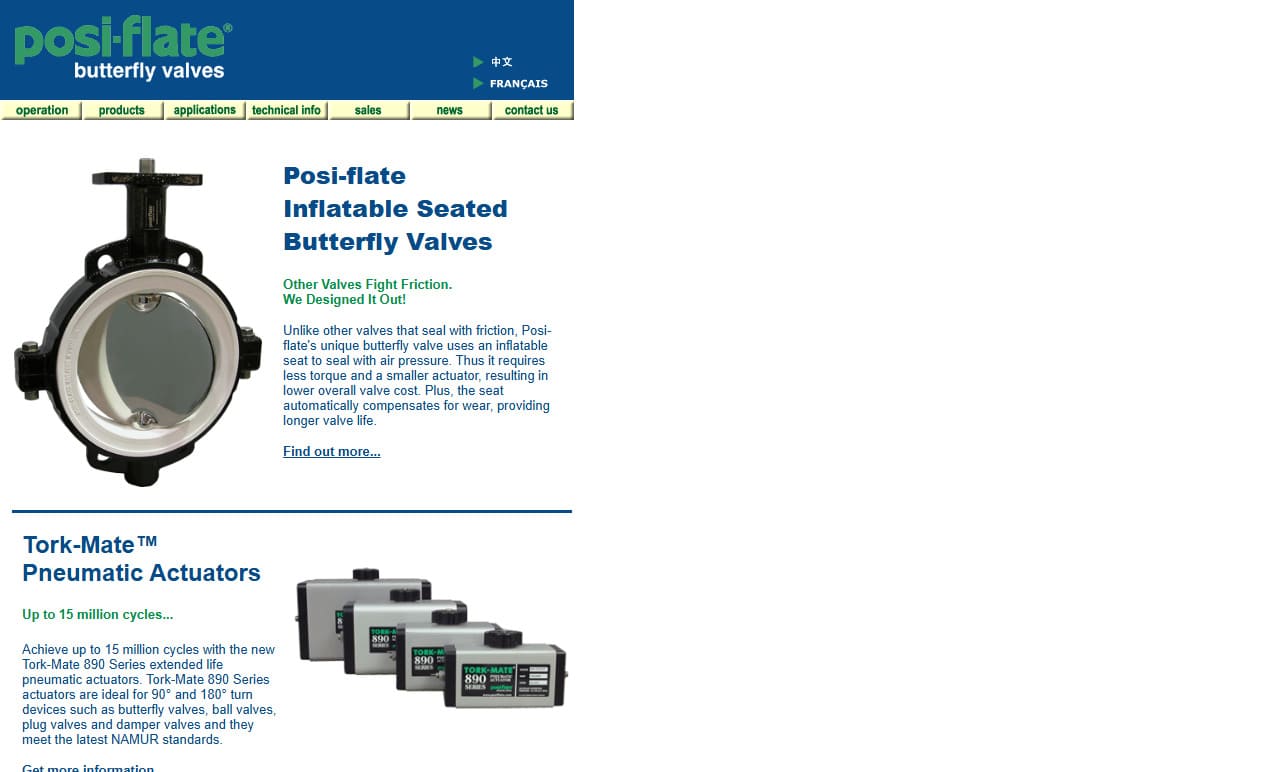

At Posi-flate, we specialize in manufacturing high-performance butterfly valves designed to meet the demanding requirements of a wide range of industrial applications. We engineer our valves with a unique inflatable seat design that ensures a tight seal with minimal torque, offering exceptional reliability, reduced wear, and longer service life.

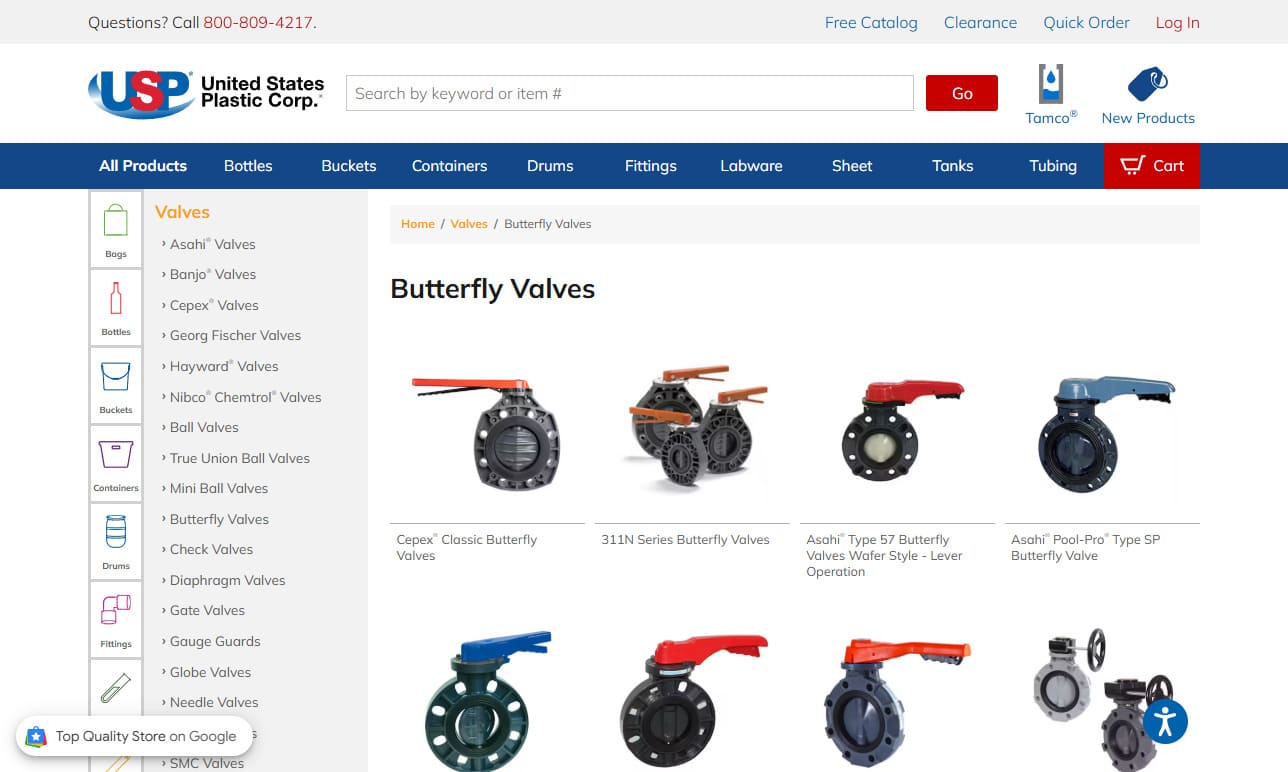

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver reliable solutions that help businesses maintain efficiency and safety in their operations.

More Butterfly Valve Design Manufacturers

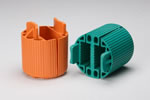

Butterfly valves typically pivot on axes perpendicular to the direction of flow inside the flow chamber and are situated on a spindle that allows for flow in a single direction. They are frequently used as throttling devices, controlling the levels of flow in entirely closed, entirely open or partially open positions. Butterfly valve suppliers stock numerous closure types and body configurations, depending on the type of flow control needed and the design.

Butterfly valves are commonly composed of metals like cast iron, aluminum and stainless steel, but can also be made from various plastics. Butterfly valves are designed and sold in many diameters, resulting in different flow rates. Smaller butterfly valve assemblies may be used where space is limited. Butterfly valves are used in many food transporting and chemical plants where controllable product flow is required. Other specific applications include HVAC, petroleum recovery and industries that use high pressure water.

Butterfly valves are fairly simple in design. When prompted, the disc rotates and stands upright in the pipe, resting on a seal or gasket and forming a tight seat. The design offers many benefits. First of all, they generally have a long life cycle. Butterfly valves are easy to maintain, lightweight and compact and able to handle a wide range of temperatures.

These valves are also very reliable because of their tight shutoff, reducing the amount of leakage. These butterfly valves are categorized as rotary valves, which are generally recognized by the quarter turn that is used to move from the open to closed position and back again. This results in a lower surface friction, which means that these valves can be smaller than others and still operate efficiently.

Compared with ball valves, butterfly valves do not have pockets to trap fluids when the valve is in the closed position. A certain kind, flanged butterfly valves, can be mounted between flanges. Another, the lug butterfly valve, uses metal inserts that are attached to the valve's bolt holes. Using an independent set of bolts for each flange, this butterfly valve's assembly is fixed between two flanges. Finally, wafer butterfly valves are the cheapest and most popular type of butterfly valves because of their simplicity and ease of use.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services