Answer: Butterfly valves are integral to air and water cooling systems due to their ability to efficiently regulate fluid and gas flow, their compact design, and their cost-effectiveness.

These systems—found in industrial processes, HVAC, power generation, and more—rely on butterfly valves to manage cooling media (water or air) to maintain optimal temperatures.

In air and water cooling systems, butterfly valves excel at balancing efficiency, cost, and functionality. They regulate and isolate flows of water or air to dissipate heat effectively, supporting everything from industrial processes to climate control. By choosing valves with appropriate materials and designs—such as high-performance models for demanding conditions—they ensure reliable cooling performance while minimizing energy and maintenance costs.

Role in Air and Water Cooling

Air and water cooling systems dissipate heat from equipment or environments, and butterfly valves control the flow of cooling media to achieve this effectively.

Water Cooling Systems

- Flow Regulation:

- In water-based cooling systems (e.g., chillers, cooling towers, or heat exchangers), butterfly valves adjust the volume of water circulating through the system. By throttling the valve, operators can control cooling rates to match heat loads, preventing overcooling or insufficient heat removal.

- Isolation:

- They isolate sections of the system—like a cooling tower or pump—for maintenance without shutting down the entire setup. This ensures continuous operation in critical applications like data centers or industrial plants.

- Distribution:

- In multi-zone cooling systems, butterfly valves direct water to specific areas (e.g., individual radiators or process units), optimizing resource use and maintaining consistent temperatures across the system.

Air Cooling Systems

- Airflow Control:

- In air-cooled systems (e.g., HVAC units or forced-air heat exchangers), butterfly valves regulate the volume of air passing through ducts or over cooling fins. Adjusting the valve position modulates airflow to balance cooling efficiency with energy consumption.

- Duct Isolation:

- They act as shutoff valves in ductwork to isolate zones for repairs, cleaning, or to redirect air in response to changing cooling demands (e.g., in large commercial buildings).

- Fan Integration:

- Positioned downstream of fans or blowers, butterfly valves throttle airflow to prevent excessive cooling or to maintain pressure in systems like air-cooled condensers.

Advantages in Air and Water Cooling

- High Flow Capacity: When fully open, butterfly valves provide minimal resistance, allowing efficient movement of large volumes of water or air, critical for high-capacity cooling systems.

- Quick Response: The quarter-turn operation enables rapid adjustments to changing thermal conditions, improving system responsiveness.

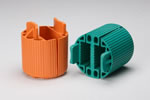

- Compact Design: Their lightweight, slim profile fits easily into piping or ducting, ideal for space-limited installations like rooftop HVAC units or industrial cooling towers.

- Cost Efficiency: Compared to gate or globe valves, butterfly valves offer a lower-cost solution for large-diameter applications common in cooling systems.

- Durability: Materials like stainless steel, cast iron, or PVC (for water) and resilient seals (e.g., EPDM) withstand corrosion, temperature variations, and wear from continuous operation.

Specific Applications

- Cooling Towers: Regulate water flow to the tower or between basins, controlling evaporation rates and heat dissipation in power plants or manufacturing facilities.

- Chillers: Manage chilled water distribution to air handlers or process equipment, ensuring precise temperature control in HVAC or industrial cooling.

- Heat Exchangers: Adjust water or air flow across exchanger surfaces to optimize heat transfer, as in automotive radiators or chemical processing.

- HVAC Systems: Control air supply in ducted systems or water flow in hydronic cooling setups, maintaining comfort in buildings or data centers.

- Power Generation: Handle cooling water in turbine condensers or air in gas turbine exhaust systems, critical for efficient energy production.

Design Considerations

- Material Selection:

- For water cooling, valves might use PVC or bronze for low-pressure systems, or stainless steel for high-pressure or corrosive environments. In air systems, lightweight aluminum or coated steel resists humidity-induced corrosion.

- Sealing: Resilient seats (e.g., rubber or PTFE) ensure leak-tight closure, preventing water loss or air leakage that could reduce cooling efficiency.

- Pressure and Temperature Ratings: Valves must handle typical cooling system pressures (e.g., 50-150 psi for water) and temperatures (up to 200°F or higher in industrial settings).

- Actuation: Automated butterfly valves with electric or pneumatic actuators enable remote or precise control, common in large-scale or dynamic cooling setups.

Limitations

- Fine Throttling: Butterfly valves are less precise for minute flow adjustments compared to globe valves, which can affect systems needing exact temperature control.

- Cavitation Risk: In high-velocity water systems, improper sizing or operation can lead to cavitation, damaging the valve or piping.

- Debris Sensitivity: In water cooling, sediment or particulates can wear seals or jam the disc, requiring filtration or regular maintenance.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services