Answer: Butterfly valves are widely used in vacuum systems due to their simplicity, reliability, and ability to control gas flow effectively. Butterfly valves are a versatile choice in vacuum systems for regulating and isolating gas flow, particularly in low- to medium-vacuum applications. Their design balances efficiency, cost, and functionality, making them a staple in industries and research facilities relying on vacuum technology.

Here’s how they function and are applied in such systems:

How Butterfly Valves Work

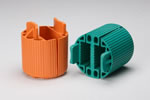

A butterfly valve consists of a circular disc (the “butterfly”) mounted on a rotating shaft. When the valve is fully open, the disc is perpendicular to the flow, allowing maximum conductance (gas flow). When closed, the disc rotates parallel to the flow, sealing against a seat to block or restrict gas passage. This quarter-turn operation makes them quick and efficient for modulating flow.

Applications in Vacuum Systems

- Flow Regulation:

- In vacuum systems, butterfly valves are used to regulate the flow of gases between chambers or into the system from external sources. By partially opening or closing the valve, operators can fine-tune pressure levels, which is critical for processes like thin-film deposition or vacuum drying.

- Isolation:

- They serve as isolation valves to separate different sections of a vacuum system, such as between a vacuum pump and a chamber. This allows maintenance or process changes in one section without breaking the vacuum in others.

- Throttle Control:

- Butterfly valves are often placed between a vacuum pump and a chamber to throttle the pumping speed. This helps maintain a specific pressure range, preventing over-evacuation or damage to sensitive components.

- High Vacuum Environments:

- In high-vacuum systems (e.g., pressures below 10⁻³ Torr), butterfly valves with appropriate sealing materials (like Viton or metal seals) are used to ensure leak-tight operation, minimizing gas ingress that could compromise the vacuum level.

Advantages in Vacuum Systems

- Compact Design: Their lightweight and slim profile make them ideal for space-constrained vacuum setups.

- High Conductance: When fully open, they offer minimal resistance to gas flow, preserving vacuum pump efficiency.

- Quick Operation: The 90-degree turn from open to closed enables rapid response, essential for dynamic vacuum processes.

- Cost-Effectiveness: Compared to gate or ball valves, butterfly valves are generally less expensive and easier to maintain.

Limitations

- Not Ideal for Ultra-High Vacuum (UHV): In ultra-high vacuum systems (below 10⁻⁹ Torr), butterfly valves may not provide the hermetic sealing required, where gate valves or all-metal valves are preferred.

- Pressure Differential: They’re less effective against high differential pressures unless specifically designed with reinforced seals.

- Particle Generation: In some cases, the disc movement can generate particles, which might contaminate sensitive vacuum processes like semiconductor manufacturing.

Practical Examples

- Semiconductor Industry: Used to control gas flow during etching or deposition processes in vacuum chambers.

- Research Labs: Employed in experimental setups to adjust vacuum levels for physics or materials science experiments.

- Industrial Vacuum Systems: Found in freeze-drying or vacuum packaging, where precise pressure control enhances product quality.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services