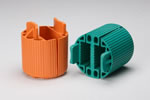

Operators of plastic butterfly valves can control the flow of a fluid or gas by pulling a lever that opens or closes the valve. In the open position, the round disc sits perpendicular to the seal around the pipe. Read More…

Butterfly Valves & Controls, Inc. has been a premier supplier of quality butterfly control valves and other related industrial components for 25 years. We carry only the best parts sourced from world-class butterfly valve manufacturers. Extended service life and safe operation are at the core of every valve manufactured/assembled. Our catalog includes a large selection of valves, actuators, controls, positioners, and more.

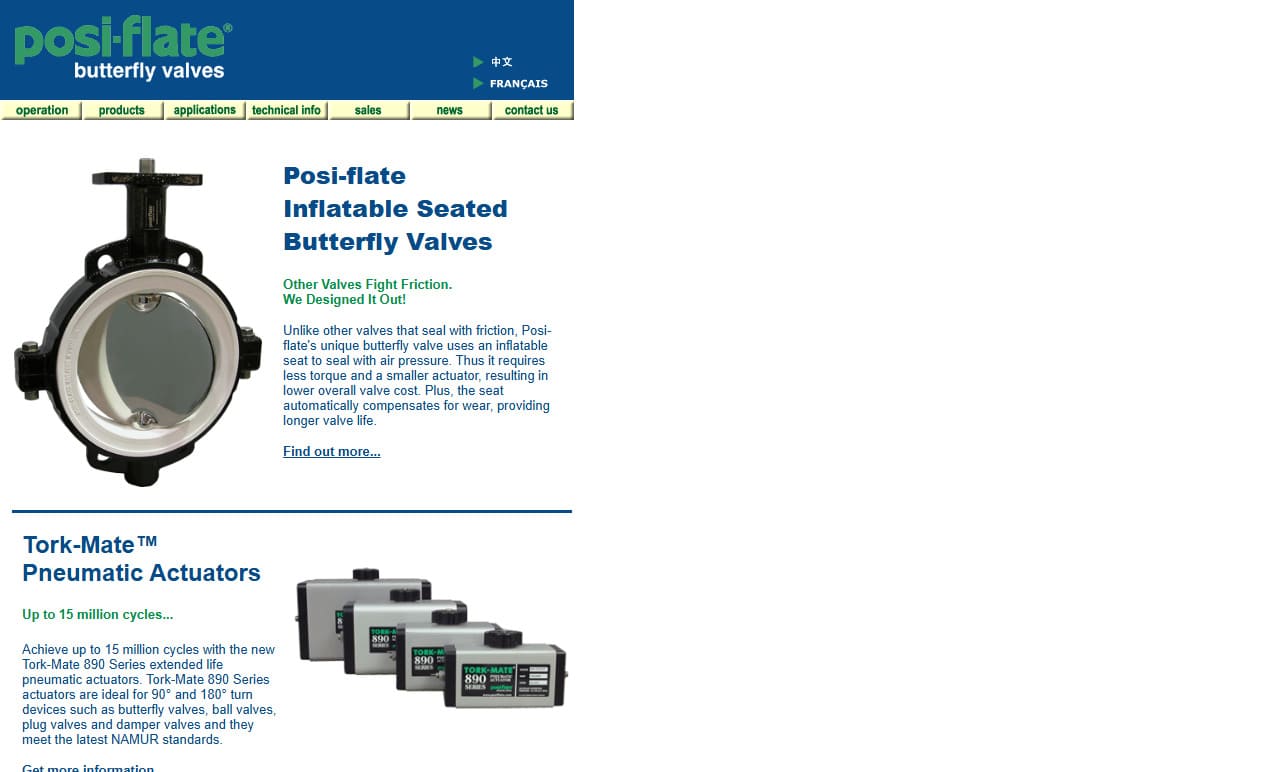

At Posi-flate, we specialize in manufacturing high-performance butterfly valves designed to meet the demanding requirements of a wide range of industrial applications. We engineer our valves with a unique inflatable seat design that ensures a tight seal with minimal torque, offering exceptional reliability, reduced wear, and longer service life.

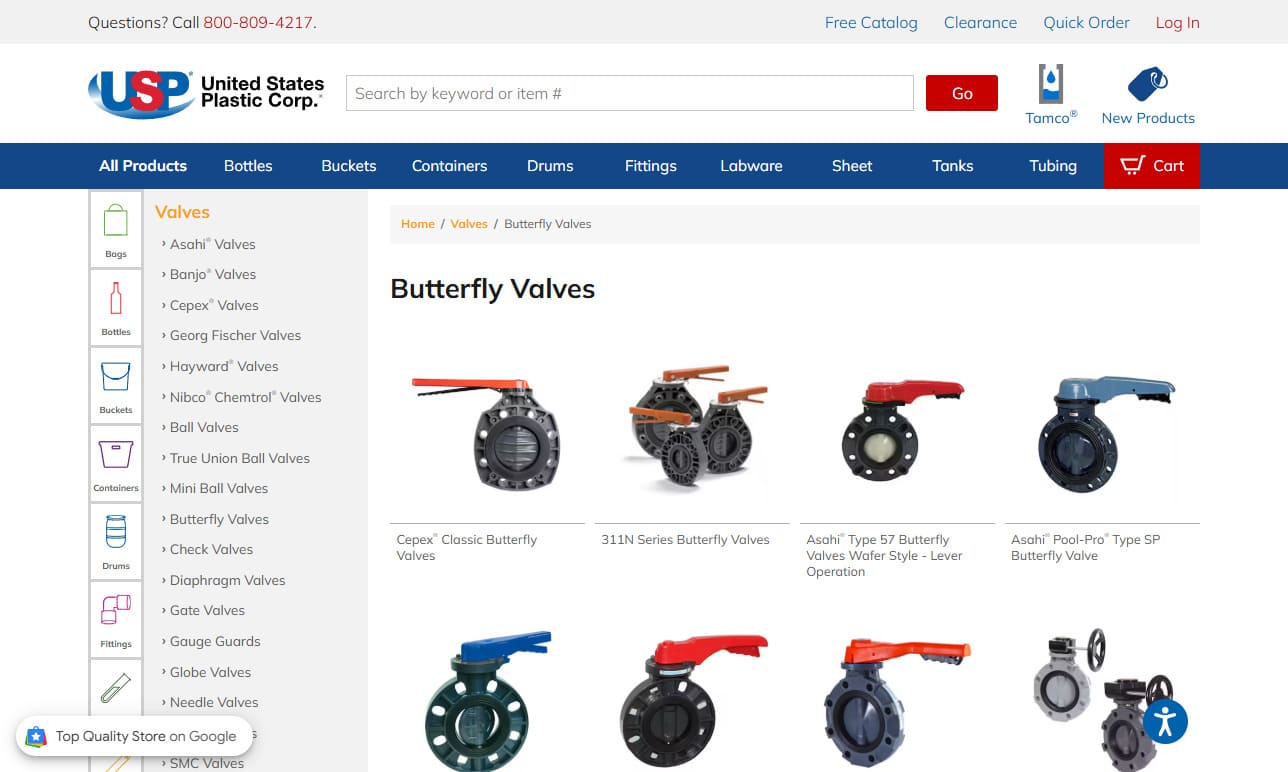

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver reliable solutions that help businesses maintain efficiency and safety in their operations.

More Plastic Butterfly Valve Manufacturers

When the lever is pulled or rotated, however, the disc rotates around so that it fits snugly into the seal and blocks all flow. In other words, the disc has two positions, either parallel or perpendicular to the flow of water. Butterfly valve manufacturers have created plastic valves in particular for their low product cost and flexibility. Other common materials include aluminum, for its light and flexible nature, which makes it a perfect gasket, and stainless steel for its strength and corrosion resistance. Plastic butterfly valves may be cheaper, but they are not as popular as their metal counterparts, mostly because of vulnerability to chemical corrosion. A breakdown of the valve means leaks and damage, so there are companies who do not take the risk.

Other factors besides the basic material separates one butterfly valve from another, and most of these differences can be incorporated into a plastic design as well as a metal. If the piping system is going to consist of very high pressures, then a high performance valve is used, as a pneumatic one is employed in very low pressure systems.

For companies that require the ultimate sealant guarantee, the triple offset butterfly valve should alleviate their fears. This valve is arranged in such a way that it can be turned three different positions and still contain a leak, while also allowing a safeguard against emergency shut off.

The pressure of the system, the fluids flowing through it and the variety of uses the butterfly valve must serve are all considerations a consumer must ponder before purchasing one of a thermoplastic nature or metal. Because of the advances in machining, the parts for butterfly valves as well as other tools can be precise as long as the consumer knows exactly what they need.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services