Sanitary butterfly valves are essential flow control components used in hygienic and aseptic processing systems. Engineered for industries that require strict contamination control, these valves regulate the movement of liquids, viscous materials, and slurries through piping networks while meeting rigorous sanitary standards. Read More…

Butterfly Valves & Controls, Inc. has been a premier supplier of quality butterfly control valves and other related industrial components for 25 years. We carry only the best parts sourced from world-class butterfly valve manufacturers. Extended service life and safe operation are at the core of every valve manufactured/assembled. Our catalog includes a large selection of valves, actuators, controls, positioners, and more.

At Posi-flate, we specialize in manufacturing high-performance butterfly valves designed to meet the demanding requirements of a wide range of industrial applications. We engineer our valves with a unique inflatable seat design that ensures a tight seal with minimal torque, offering exceptional reliability, reduced wear, and longer service life.

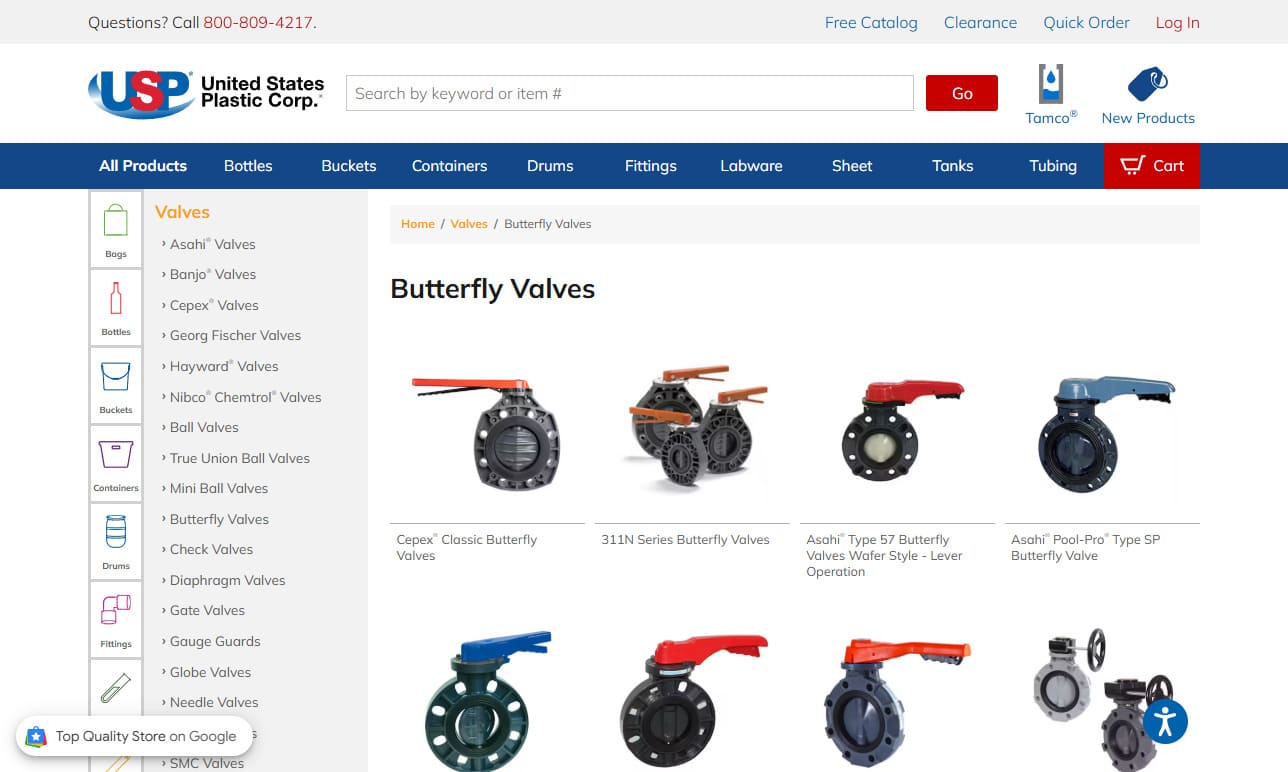

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver reliable solutions that help businesses maintain efficiency and safety in their operations.

More Sanitary Butterfly Valve Manufacturers

Their design emphasizes cleanability, durability, and precision, making them a staple in sectors like food and beverage, pharmaceuticals, biotechnology, dairy processing, and personal care manufacturing.

The valves operate using a quarter-turn mechanism that rotates a centrally mounted disc to open or close the passageway. With their compact build, easy operation, and polished stainless-steel surfaces, sanitary butterfly valves deliver reliable sealing and ease of maintenance. They are an integral part of hygienic piping systems, particularly in facilities where frequent cleaning and sterilization cycles are required to maintain product quality and safety.

Key Applications of Sanitary Butterfly Valves

Sanitary butterfly valves are relied upon wherever contamination prevention and strict hygiene protocols are enforced. In beverage bottling plants, they regulate juice, beer, and carbonated drink production, while dairy processors use them for milk, cream, and yogurt transfer. Pharmaceutical facilities use these valves to maintain sterility during the handling of active ingredients and formulations, and biotechnology operations employ them to preserve integrity in sensitive fluid processes.

The cosmetic and personal care sectors also integrate sanitary butterfly valves to process lotions, gels, and skincare products with precision. Beyond these industries, they are employed in water filtration systems, clean-in-place (CIP) loops, and specialty chemical processes where high purity is essential. Their adaptability and dependable sealing performance make them ideal for both continuous production lines and batch-based manufacturing setups.

Design Features and Operating Principles

Sanitary butterfly valves feature a simple yet highly effective construction. The core element is a disc attached to a shaft or stem, which rotates to control flow. When aligned with the pipeline, the disc allows fluid to pass freely with minimal pressure loss; rotated 90 degrees, it forms a tight seal, halting flow completely. This quarter-turn operation provides rapid and precise control, supporting system efficiency and reliability.

The valve’s internal surfaces are polished to prevent product buildup, reduce bacterial growth, and streamline cleaning. Most models are manufactured from 304 or 316L stainless steel for superior corrosion resistance, while elastomeric seals such as EPDM, silicone, or Viton® ensure compatibility with a wide range of chemicals and temperatures. Sanitary butterfly valves can be manually operated with lever handles or integrated into automated systems with pneumatic or electric actuators.

Connection types vary to suit facility needs: tri-clamp fittings enable quick disassembly, weld ends provide permanent installation, and threaded connections offer versatility. These design variations allow seamless integration into new or existing sanitary processing lines.

Benefits of Using Sanitary Butterfly Valves

Sanitary butterfly valves are favored for their balance of affordability, performance, and hygienic design. Their compact construction reduces installation space while providing exceptional sealing and durability. Maintenance is simplified thanks to their minimal components and straightforward design, which makes disassembly and cleaning faster compared to other valve types.

Another key advantage is their ability to withstand harsh cleaning and sterilization cycles, including steam-in-place (SIP) and caustic cleaning agents, without degrading performance. Their smooth internal pathways minimize turbulence and reduce the risk of cross-contamination, making them a practical solution for industries with strict regulatory requirements.

Cost efficiency is another factor in their popularity; high-performance butterfly valves provide robust performance at a lower price point compared to ball or diaphragm valves, while still delivering the hygienic features and compliance standards required in sanitary processing.

Considerations for Selection

Choosing the right sanitary butterfly valve involves analyzing product type, operating temperature, pressure requirements, and system layout. Stainless steel 316L is often preferred for its enhanced corrosion resistance, while seal material selection ensures chemical compatibility. Facilities that require frequent cleaning typically opt for tri-clamp connections to simplify disassembly, while permanent systems may favor welded connections for added security.

Automation needs also play a role in valve selection. Pneumatic or electric actuation allows for centralized control and integration with programmable logic controllers (PLCs), making them suitable for high-throughput production environments. Buyers often prioritize valves from trusted butterfly valve manufacturers with certifications like 3-A Sanitary Standards, EHEDG, or ASME BPE to ensure compliance with food safety and pharmaceutical regulations.

Importance of Sanitary Processing Systems

Sanitary butterfly valves are integral to ensuring safe, efficient, and contamination-free production environments. Their polished surfaces and crevice-free interiors support the highest levels of hygiene, while their modular construction makes routine maintenance and part replacement straightforward. Industries with strict quality control requirements benefit from the reliability and traceability these valves offer, especially when paired with CIP/SIP systems that eliminate the need for manual cleaning between production cycles.

Their ability to handle both high and low-viscosity products without compromising seal integrity makes them versatile for a broad spectrum of applications. From craft breweries to pharmaceutical cleanrooms, sanitary butterfly valves have proven indispensable for maintaining operational efficiency and protecting product integrity.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services