Like all butterfly valves, stainless steel butterfly valves consist of a seal around a pipe wall, a round disc or plate and a control lever. Read More…

Butterfly Valves & Controls, Inc. has been a premier supplier of quality butterfly control valves and other related industrial components for 25 years. We carry only the best parts sourced from world-class butterfly valve manufacturers. Extended service life and safe operation are at the core of every valve manufactured/assembled. Our catalog includes a large selection of valves, actuators, controls, positioners, and more.

At Posi-flate, we specialize in manufacturing high-performance butterfly valves designed to meet the demanding requirements of a wide range of industrial applications. We engineer our valves with a unique inflatable seat design that ensures a tight seal with minimal torque, offering exceptional reliability, reduced wear, and longer service life.

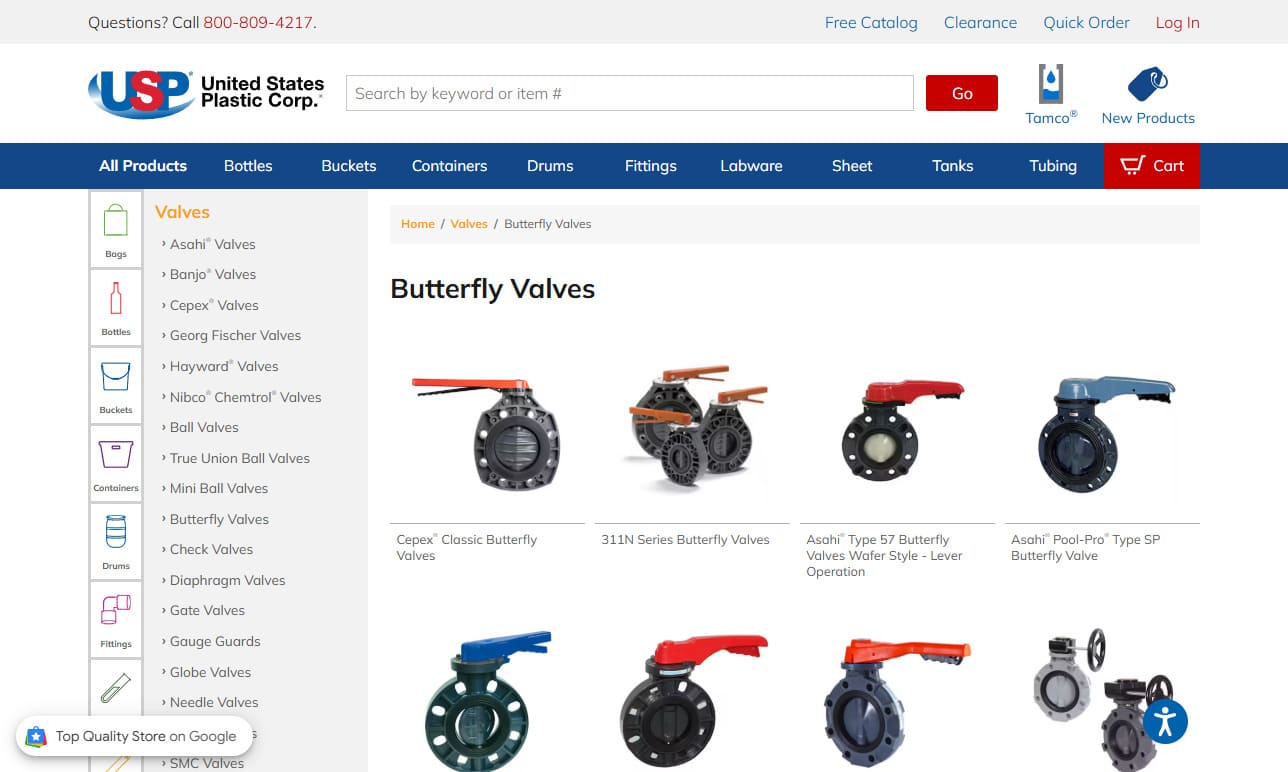

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver reliable solutions that help businesses maintain efficiency and safety in their operations.

More Stainless Steel Butterfly Valve Manufacturers

Stainless Steel Butterfly Valves: Comprehensive Guide, Applications, and Buyer Insights

Stainless steel butterfly valves are a crucial component in a wide variety of industrial piping systems, known for their robust performance, durability, and exceptional resistance to corrosion. The body and disc of these valves are constructed from high-grade stainless steel materials, making them a preferred choice for industries that demand long-lasting and reliable flow control solutions. In this guide, we will explore everything you need to know about stainless steel butterfly valves—including their benefits, key applications, selection criteria, and how they compare to other valve materials such as cast iron and plastic.

What Is a Stainless Steel Butterfly Valve?

A stainless steel butterfly valve is a flow regulation device featuring a disc that rotates to open or close the passage of liquids or gases through a pipe. The primary components—the valve body and disc—are fabricated from stainless steel, a metal alloy celebrated for its corrosion resistance, longevity, and hygienic properties. This makes stainless steel butterfly valves ideal for industries where sanitation and durability are paramount, such as food and beverage processing, pharmaceuticals, water treatment, and chemical manufacturing.

Why Choose Stainless Steel for Butterfly Valves?

Stainless steel offers unique advantages over other common valve materials, including:

- Corrosion Resistance: Stainless steel naturally resists rust and oxidation, even in harsh chemical environments or when exposed to water and moisture. This translates to a longer service life and reduced maintenance costs.

- Sanitary Properties: Stainless steel is non-porous and easy to clean, making it ideal for applications where cleanliness is critical, such as food processing, pharmaceuticals, and potable water systems.

- Mechanical Strength: The material withstands high pressures and extreme temperatures, allowing it to perform reliably in demanding industrial and commercial settings.

- Low Maintenance: Due to its resistance to scaling, fouling, and corrosion, stainless steel requires less frequent servicing and replacement compared to other metals.

- Aesthetic Appeal: Stainless steel maintains its appearance over time, which can be important in visible or exposed installations.

How Do Stainless Steel Butterfly Valves Work?

Stainless steel butterfly valves operate via a simple yet effective mechanism. The valve contains a rotating disc that pivots around a central axis. By pulling or turning a lever, operators can rotate the disc to either open, partially open, or fully close the valve. When the disc is aligned parallel to the flow of water, gas, or other process media, the valve is in the open position and allows maximum throughput. As the handle is rotated, the disc turns perpendicular to the flow, forming a tight seal that blocks passage through the pipe.

This straightforward design results in several operational benefits:

- Quick Actuation: Butterfly valves can be opened or closed rapidly, making them ideal for applications where fast shut-off or flow regulation is required.

- Compact Size: Butterfly valves are generally smaller and lighter than comparable gate or globe valves, saving space and reducing installation costs.

- Low Pressure Drop: When fully open, the disc presents minimal resistance to flow, ensuring high efficiency.

Key Applications of Stainless Steel Butterfly Valves

Stainless steel butterfly valves are highly versatile and are used across a broad spectrum of industries. Common applications include:

- Water Treatment and Distribution: Used extensively in potable water supply systems, wastewater treatment plants, and desalination facilities due to their reliability and corrosion resistance.

- Chemical Processing: Ideal for controlling aggressive chemicals, acids, and solvents thanks to stainless steel's resistance to chemical attack.

- Food and Beverage Production: The sanitary properties of stainless steel make these valves perfect for breweries, dairies, and food manufacturing plants where contamination must be avoided.

- Pharmaceutical Manufacturing: Used in sterile piping systems for medicines, vaccines, and other sensitive products.

- HVAC and Ventilation: Employed in heating, ventilation, and air conditioning systems for precise control of air and water flow.

- Oil and Gas: Utilized in pipelines, refineries, and petrochemical plants for their durability and ability to handle high pressures and temperatures.

- Fire Protection Systems: Incorporated in sprinkler and fire suppression systems due to their quick-acting shutoff capability.

- Marine and Shipbuilding: Resistant to saltwater corrosion, making them suitable for use in shipboard piping and ballast systems.

Stainless Steel vs. Cast Iron and Plastic Butterfly Valves

When selecting a butterfly valve, it's important to consider the unique properties and performance characteristics of different materials. Here’s how stainless steel compares to other common choices:

Stainless Steel vs. Cast Iron

Cast iron is another popular material used by butterfly valve manufacturers. While cast iron valves are strong, durable, and cost-effective, they have limitations:

- Corrosion Resistance: Cast iron is less resistant to corrosion than stainless steel, especially in environments with moisture, chemicals, or salt.

- Weight: Cast iron valves are typically heavier, which can complicate installation and maintenance.

- Gasket Compatibility: Cast iron cannot be used for gaskets due to its lack of flexibility and lightweight properties. Stainless steel or aluminum are usually preferred for these components.

- Applications: While cast iron is suitable for many water and HVAC systems, it is not suitable for high-purity or sanitary applications.

Stainless Steel vs. Plastic Butterfly Valves

Plastic butterfly valves are often considered for their cost-effectiveness and lightweight characteristics. However, they are generally less suitable for demanding industrial applications because:

- Chemical Resistance: While some plastics resist certain chemicals, they are generally more vulnerable to corrosion and degradation compared to stainless steel.

- Temperature and Pressure Limits: Plastic valves cannot withstand the high temperatures and pressures that stainless steel valves can handle.

- Durability: Plastics are more prone to wear and mechanical damage, shortening the valve’s operational lifespan.

- Application Scope: Plastic butterfly valves are most often used in low-pressure, non-critical systems such as irrigation, swimming pools, and some chemical handling processes.

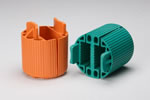

Types of Stainless Steel Butterfly Valves

Butterfly valves made from stainless steel are available in several types and configurations to suit different operational requirements. Common variations include:

- Wafer Type: Designed for tight, leak-proof installation between two pipe flanges using bolts. Ideal for most general pipeline applications.

- Lug Type: Features threaded inserts (lugs) on both sides, allowing the valve to be installed or removed independently of the piping system. Recommended for systems needing frequent maintenance or isolation.

- Double Offset (High-Performance): The disc is offset from the shaft, reducing friction and wear for high-pressure, high-temperature, or critical service applications.

- Triple Offset: Utilizes advanced engineering to achieve a bubble-tight seal, suitable for severe service conditions including steam, hydrocarbon, and corrosive chemical applications.

- Sanitary Butterfly Valves: Specially designed for clean-in-place (CIP) and sterilize-in-place (SIP) processes in food, beverage, and pharmaceutical industries.

Key Features to Consider When Buying Stainless Steel Butterfly Valves

When researching or purchasing a stainless steel butterfly valve, it’s important to assess several critical features to ensure optimal performance and return on investment. Consider the following factors:

- Valve Size and Pressure Rating: Choose a valve with the correct diameter and pressure class for your pipeline system to ensure safe and efficient operation.

- Disc and Seat Material: While the body and disc are typically stainless steel, seat materials may vary (e.g., PTFE, EPDM, NBR) to suit different media and temperature requirements.

- Actuation Method: Valves can be operated manually (lever or gear), pneumatically, or electrically. Automated actuators are ideal for remote control or integration with process automation systems.

- End Connections: Wafer, lug, or flanged connections affect installation and maintenance procedures.

- Compliance and Certifications: For food, pharmaceutical, or potable water applications, ensure the valve meets relevant standards such as FDA, NSF, or ISO certifications.

- Maintenance and Serviceability: Look for valves with easily replaceable seals and minimal moving parts to simplify upkeep.

Benefits of Using Stainless Steel Butterfly Valves

The use of stainless steel butterfly valves offers a range of important advantages over alternative flow control devices. Key benefits include:

- Longevity: Stainless steel extends the operational life of valves, reducing the frequency of replacement and downtime.

- Cost-Effectiveness: While the initial investment may be higher than plastic or cast iron, the total cost of ownership is lower due to reduced maintenance and replacement costs.

- Versatility: Suitable for a broad range of fluids, including water, chemicals, steam, oil, and food-grade liquids.

- Reduced Contamination Risk: The non-reactive surface minimizes the risk of process contamination, crucial in sanitary and high-purity applications.

- Environmentally Friendly: Stainless steel is recyclable, contributing to sustainability initiatives.

- Quick Installation: Lightweight design and simple mechanisms facilitate fast and easy installation, even in tight or complex piping systems.

Common Use Cases for Stainless Steel Butterfly Valves

Understanding the specific use cases for stainless steel butterfly valves can help you determine where they fit best in your process pipeline. Typical scenarios include:

- On/Off Flow Regulation: Quickly stopping or starting flow in water, chemical, or gas pipelines.

- Throttling Control: Adjusting the valve disc to partially open positions to modulate flow rates as needed.

- Emergency Shutoff: Rapidly isolating sections of a piping system during leaks or process upsets.

- Sanitary Processing: Maintaining clean, safe, and sterile flow paths for food, beverage, and pharmaceutical products.

- Corrosive Chemical Handling: Providing long-lasting control in systems that transport acids, caustics, or other aggressive media.

- High-Temperature Applications: Managing steam and hot water systems without degrading valve performance.

- Fire Safety: Acting as quick-acting shutoff valves in fire suppression and sprinkler systems.

Installation and Maintenance Tips for Stainless Steel Butterfly Valves

Proper installation and maintenance are critical to maximizing the lifespan and reliability of your stainless steel butterfly valves. Here are some best practices:

- Correct Alignment: Ensure the valve is properly centered between flanges to avoid leaks and ensure smooth operation.

- Tighten Bolts Evenly: Follow a star pattern when tightening flange bolts to distribute pressure evenly and prevent warping.

- Inspect Seals and Seats: Regularly check for wear or damage to the disc seat and replace as needed to maintain a tight seal.

- Lubricate Moving Parts: Use compatible lubricants on the stem and actuator to prevent corrosion and ensure smooth movement.

- Cycle the Valve: Periodically open and close the valve to prevent sticking and confirm full range of motion.

- Follow Manufacturer Guidelines: Always reference the manufacturer’s installation and maintenance documentation for best results.

Frequently Asked Questions About Stainless Steel Butterfly Valves

- Which grade of stainless steel is best for butterfly valves? Common grades include 304 and 316 stainless steel. 316 offers enhanced corrosion resistance, making it suitable for chemical and marine applications.

- Can stainless steel butterfly valves be used for drinking water? Yes, provided the valve is certified to NSF/ANSI 61 or equivalent potable water standards.

- How do I choose between manual, electric, and pneumatic actuation? Manual is suitable for simple, infrequent operation. Electric and pneumatic actuators are recommended for automated or remote-controlled systems.

- What are the main maintenance requirements? Regular inspection, cleaning, and occasional replacement of seals and seats are typically all that’s required.

- How do I size a butterfly valve for my application? Consider the pipe diameter, flow rate, pressure, and type of media. Consult with a valve specialist or use an online sizing tool for precise calculations.

Have more questions? Contact our valve experts for personalized support.

Where to Buy High-Quality Stainless Steel Butterfly Valves

When sourcing stainless steel butterfly valves, it’s essential to partner with reputable manufacturers and distributors who offer certified, high-quality products. Look for suppliers that provide:

- Comprehensive product catalogs with detailed specifications

- Fast delivery and robust after-sales support

- Custom fabrication and engineering services for unique applications

- Competitive pricing and bulk order discounts

- Compliance with industry standards and certifications

Ready to purchase or compare stainless steel butterfly valve options? Find leading butterfly valve manufacturers here.

Conclusion: Is a Stainless Steel Butterfly Valve Right for Your System?

Stainless steel butterfly valves deliver unmatched performance, longevity, and versatility across a wide range of industrial, commercial, and sanitary applications. Their superior resistance to corrosion, easy maintenance, and adaptability make them a top choice for engineers, plant managers, and facility operators. Whether you are upgrading a water treatment system, managing chemical process flows, or installing a new sanitary pipeline, stainless steel butterfly valves provide a cost-effective and reliable solution.

Still have questions about selecting, installing, or maintaining stainless steel butterfly valves? Contact our team of valve experts for personalized guidance and recommendations.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services