A triple-offset butterfly valve has three different offsets (balancing effects). The first offset relates to the location of the shaft in reference to the centerlines of the bore. The second offset is in the design of the seat cone angle. The geometrical design of the sealing components makes up the third offset. Each sealing component has an offset conical profile that results in a right-angled cone because of the way it was machined. This guarantees friction-free stroking throughout the whole cycle of operation. The disc seat does not over-travel since contact is only made at the very last moment of closing, with the 90-degree angle serving as a mechanical stop. Read More…

Butterfly Valves & Controls, Inc. has been a premier supplier of quality butterfly control valves and other related industrial components for 25 years. We carry only the best parts sourced from world-class butterfly valve manufacturers. Extended service life and safe operation are at the core of every valve manufactured/assembled. Our catalog includes a large selection of valves, actuators, controls, positioners, and more.

At Posi-flate, we specialize in manufacturing high-performance butterfly valves designed to meet the demanding requirements of a wide range of industrial applications. We engineer our valves with a unique inflatable seat design that ensures a tight seal with minimal torque, offering exceptional reliability, reduced wear, and longer service life.

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver reliable solutions that help businesses maintain efficiency and safety in their operations.

More Triple Offset Butterfly Valve Manufacturers

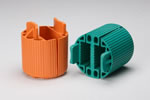

Deconstruction of the Triple-Offset (Butterfly) Valve/TOV

The triple-offset butterfly valve, often referred to as a TOV (Triple Offset Valve), is a highly engineered valve solution designed for demanding industrial flow control applications. These valves incorporate three distinct offsets in their design, which work in unison to create a continuous sealing surface, minimize wear between the seat and seal, and maintain exceptional sealing integrity throughout the valve's operational life. The carefully adjusted seat angle also eliminates disc sticking or binding and reduces the valve's operating torque, making TOVs ideal for precise flow regulation and shut-off duties.

In terms of cost-effectiveness, triple-offset butterfly valves are generally more affordable than other metal-seated valves while delivering superior sealing capabilities. As a result, they are frequently chosen for critical applications such as petrochemical refining, oil and gas transport, and power generation. Their lightweight construction, quarter-turn operation, and straightforward installation requirements mean that TOVs require less pipe bracing and are easy to install, integrate, and maintain within existing piping systems. Additional cost savings arise from features such as a removable seal ring, which enables rapid repairs, and their inherently low torque requirements, which allow for the use of smaller, more economical actuators.

Are you evaluating triple-offset butterfly valves for your next project? Learn about common use cases and industry applications below.

Traditional Applications and Modern Trends Regarding Triple-Offset Valves

Historically, triple-offset valves have been essential in a diverse range of industrial systems where reliable, bubble-tight shut-off and resistance to extreme conditions are paramount. This includes applications such as desalination, municipal and industrial water treatment and distribution, pulp and paper processing, district heating, electricity production, and oil and gas refining.

Triple-offset butterfly valves have also been widely adopted in chemical processing plants, petrochemical facilities, offshore oil and gas platforms, steel manufacturing, sugar mills, and even in advanced power plants handling superheated steam. Their versatility continues to grow as industries face stricter governmental regulations, heightened safety standards, and expanding production requirements. The ability of TOVs to meet rigorous performance and compliance standards has driven their increased deployment across both established and emerging sectors.

The unique operational benefits of triple-offset valves—including high efficiency, robust resistance to corrosive chemicals and aggressive media, capacity for handling high-pressure and high-temperature materials, and adaptability to fluctuating process conditions—have made them a preferred choice worldwide. Each new generation of triple-offset butterfly valves introduces additional features for improved safety, durability, and efficiency, building upon proven design principles to deliver enhanced value to end users.

Metal-to-Metal Sealing: Optimal Performance in Extreme Conditions

A signature feature of the triple-offset butterfly valve is its precision-engineered metal-to-metal sealing system. By employing a high-precision machined metal seat and seal ring, TOVs provide a long-lasting, bi-directional, near-zero leakage shutoff. This is especially critical in high-temperature and high-pressure environments—such as those found in hydrocarbon processing, steam lines, and critical isolation applications—where traditional elastomeric or soft-seated valves would quickly fail.

The robust metal-to-metal seat design also ensures that the valve can withstand rapid temperature fluctuations and thermal cycling, maintaining sealing integrity even under fire-safe conditions. The TOV's right-angled conical geometry, coupled with its quarter-turn operation, enables low-friction in-line sealing and repeatable, reliable operation—qualities that are vital for fire protection systems, emergency shutdowns, and other mission-critical services.

Optimized Seat Angle: Enhanced Durability and Reduced Maintenance

Another key engineering advancement in triple-offset butterfly valves is the optimized seat angle, often augmented by the use of hard-facing materials such as Stellite®. This configuration yields a longer seal life, improved abrasion resistance, and greater durability—even after thousands of operational cycles. The enhanced seat angle minimizes the risk of disc wedging or binding, further reducing maintenance needs and ensuring smooth, consistent valve operation.

Advantages of Triple-Offset Butterfly Valves

A triple-offset butterfly valve (TOV) features three critical design offsets: two relating to the shaft's position relative to the bore and the sealing surfaces' disc and seat centerlines, and a third in the axis of the seat cone angle. This unique configuration is vital for applications demanding absolutely bubble-tight shutoff, where leakage could result in catastrophic process failures, environmental hazards, or safety risks.

While double-offset butterfly valves are suitable for many flow control applications, they cannot consistently achieve the zero-leakage performance required in critical isolation scenarios—an area where triple-offset butterfly valves excel. Traditional butterfly valves may also struggle in systems involving corrosive chemicals, abrasive slurries, or particulate-laden fluids, but TOVs routinely deliver reliable service in these challenging environments. Here are some of the most valuable benefits triple-offset butterfly valve technology brings to your operation:

- Cam-action and right-angled conical sealing: Ensures that metal sealing components only make contact when the valve is fully closed, leading to reproducible, reliable sealing and significantly extending the valve’s service life.

- Zero-leakage, bubble-tight shutoff: Metal-to-metal sealing guarantees absolute isolation, protecting downstream processes and reducing the risk of environmental contamination.

- Superior resistance to abrasive and corrosive media: The all-metal construction, with no elastomers or polymers, prevents swelling, degradation, and chemical attack, making TOVs ideal for harsh chemical, petrochemical, and offshore applications.

- Non-rubbing, non-binding operation: The geometric design eliminates friction between sealing parts during operation, reducing torque requirements and actuator size while extending component lifespan.

- Clog-free, low-maintenance performance: The absence of voids and elastomeric parts means there is little risk of clogging, sludging, or buildup—resulting in lower maintenance costs and longer intervals between service.

- Fire-safe and fugitive emissions compliance: Triple-offset butterfly valves can be engineered to meet or exceed global standards for fire safety and emissions, supporting compliance in regulated industries.

- Compact, lightweight, and easy to install: Compared to gate, globe, or ball valves with similar ratings, TOVs offer a smaller footprint and are easier to retrofit into existing systems.

How Does a Triple-Offset Butterfly Valve Work?

In a triple-offset design, the first two offsets are similar to those found in double-offset valves—one offset moves the shaft behind the plane of the sealing surface, and the second positions the shaft to one side of the pipe’s centerline. The third offset introduces a conical profile to the sealing surface, creating a “cam-action” effect. This ensures that the disc does not scrape or rub against the seat during operation, only making contact when fully closed. This innovative engineering approach is what delivers the TOV’s unparalleled sealing performance and extended operational lifespan.

Common Buyer Questions: Are Triple-Offset Butterfly Valves Right for My Application?

- Do you require bubble-tight shutoff for hazardous or high-value fluids?

- Are you dealing with high temperatures, high pressures, or aggressive chemicals?

- Is your process susceptible to valve clogging or seat wear with standard designs?

- Would reducing maintenance costs and downtime improve your plant’s profitability?

- Are you looking for valves compliant with fire-safe or fugitive emissions standards?

If you answered “yes” to any of the above, a triple-offset butterfly valve may be the optimal choice for your system. Learn how to select the best TOV manufacturer below.

Uses of Triple-Offset Butterfly Valves: Industry Applications and Case Studies

Triple-offset butterfly valves are recognized for their versatility, performance, and reliability across a multitude of industrial sectors. Their ease of installation, straightforward operation, superior sealing capabilities, chemical and corrosion resistance, and ability to withstand high-pressure and high-temperature environments make them invaluable in a wide array of applications. Below, explore how TOVs are used to solve complex flow control challenges in key industries:

- Refining processes: Isolation and flow control in crude oil, gasoline, diesel, and petrochemical production lines.

- Petrochemical processing: Handling aggressive chemicals and high-temperature fluids in process plants.

- Hydrocarbon processing: Zero-leakage shutoff in pipelines carrying volatile hydrocarbons, LNG, and LPG.

- Hydrogen and oxygen plants: Safe containment and control of highly reactive and hazardous gases.

- Refrigerant and thermal fluid systems: Managing heat transfer fluids, refrigerants, and superheated steam in HVAC and industrial energy applications.

- Transfer of hot gases and gas flaring: High-integrity isolation for emissions control and combustion safety.

- Vacuum services: Leak-proof operation in vacuum chambers and negative-pressure systems.

- Pulp and paper industry: Resistance to abrasive slurries and corrosive bleaching agents.

- Water treatment and desalination: Reliable shutoff and flow regulation in potable water, wastewater, and seawater applications.

- District heating and cooling networks: Efficient isolation and flow balancing for large municipal energy systems.

- Steel and sugar mills: Durable performance in high-wear, high-temperature process lines.

- Power generation: Isolation and control in steam, gas, and combined-cycle power plants, including supercritical and ultra-supercritical units.

- Fire protection and emergency systems: Fast, reliable operation for critical safety and fire suppression lines.

- Piping systems and pipeline infrastructure: Bubble-tight shutoff in transmission and distribution networks.

Looking for Application-Specific TOV Solutions?

Not sure which triple-offset butterfly valve is best for your process? Ask an expert:

- What are the temperature, pressure, and chemical compatibility requirements in your system?

- Do you need special certifications (API, ISO, ATEX, SIL, fire-safe, or fugitive emissions)?

- Are you replacing an outdated valve or upgrading an existing facility?

Choosing the Correct Triple Offset Butterfly Valves Manufacturer

When it comes to sourcing triple-offset butterfly valves, selecting the right manufacturer or supplier is critical to ensuring long-term reliability, performance, and regulatory compliance. Here are some key factors to consider during your purchasing process:

- Industry experience: Does the manufacturer have proven expertise in designing and manufacturing triple-offset valves for your sector (oil & gas, chemical, power, water, etc.)?

- Material selection: Are the valve bodies and seats available in materials suitable for your application's media (stainless steel, Inconel, Hastelloy, Duplex, etc.)?

- Certifications and standards: Can the supplier provide valves that meet international standards such as API 609, ISO 15848, ASME, ATEX, SIL, and fire-safe/fugitive emissions requirements?

- Customization and engineering support: Is the manufacturer able to offer custom engineering, sizing, and actuation options to fit your specific needs?

- Quality assurance and testing: Do they provide third-party testing, quality documentation, and comprehensive traceability for all valve components?

- After-sales support: What warranty, technical support, and spare parts services are available?

- Lead times and logistics: Can the supplier meet your project deadlines and delivery requirements, including global shipping?

To maximize your purchasing success, it is recommended to compare at least five or six triple-offset butterfly valve manufacturers or suppliers. Use our directory of TOV suppliers, where each company profile highlights areas of expertise, product offerings, certifications, and contact details. Our proprietary website previewer allows you to quickly assess each business’s specialization, while our easy RFQ (Request for Quote) form enables you to send your requirements to multiple suppliers simultaneously.

How to Request a Quote for Triple-Offset Butterfly Valves

- Identify your application parameters (media, temperature, pressure, end connections, certifications).

- Shortlist manufacturers based on experience, reputation, and product range.

- Use our RFQ form to describe your project and request detailed quotes.

- Compare pricing, delivery, customization options, and after-sales support.

- Select the supplier that best matches your technical and commercial requirements.

Ready to start your sourcing process? Contact a valve expert for tailored assistance.

Frequently Asked Questions About Triple-Offset Butterfly Valves

- What is the difference between a triple-offset and double-offset butterfly valve?

Triple-offset valves introduce a third offset in the seat geometry, creating a cam-action and right-angled sealing motion that enables true zero-leakage performance and extended service life. Double-offset valves have two offsets but still involve some rubbing action, making them less suited for critical shutoff in severe conditions. - Are triple-offset butterfly valves suitable for modulating control?

While TOVs are primarily designed for isolation and shutoff, certain designs can be equipped with control actuators for precise throttling and modulation of flow, especially in high-performance process control systems. - What sizes and pressure classes are available?

Triple-offset butterfly valves are manufactured in a wide range of sizes (typically from 2” to 120” and beyond) and pressure classes (ANSI Class 150 through 900 and higher), with custom options available for specialized applications. - Can triple-offset butterfly valves be automated?

Yes, TOVs can be fitted with pneumatic, electric, or hydraulic actuators for fully automated operation, integration into SCADA/DCS systems, or remote control in demanding environments. - How do I maintain a triple-offset butterfly valve?

Thanks to their non-rubbing seat design and robust materials, TOVs require minimal maintenance. Periodic inspection and seal replacement (if required) are typically all that is needed to ensure reliable performance.

Key Takeaways: Why Choose Triple-Offset Butterfly Valves?

- Unmatched sealing integrity for critical isolation and shutoff duties.

- Exceptional resistance to high pressures, temperatures, and corrosive/abrasive media.

- Long service life and reduced total cost of ownership.

- Compact, lightweight, and easy to install in new or retrofit projects.

- Compliance with global industry standards for safety and performance.

- Available with a wide range of actuation and customization options.

Ball Valves

Ball Valves Butterfly Valves

Butterfly Valves Centrifugal Pumps

Centrifugal Pumps Check Valves

Check Valves Diaphragm Valves

Diaphragm Valves Flow Meters

Flow Meters Hydraulic Pumps

Hydraulic Pumps Hydraulic Valves

Hydraulic Valves Metering Pumps

Metering Pumps Solenoid Valves

Solenoid Valves Vacuum Pumps

Vacuum Pumps Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services